Little Motor, Little Tires, Little Nitrous...

Here's a look back at the Shopmule's 2010 upgrades, inspiration for those looking to get an early start on this year's winter projects...

Shopmule Firewall / Engine Setback Mods

...Basically, it's a 10" engine / radiator setback combined with a 7" dash and 6" seat rail setback. The goal for this project was to be able to remove 100lbs of rear bumper ballast and still hook the tires up on un-prepared airport runways and such. It may look like radical surgery, but it's not that hard...I used a Sawzall and a MIG welder using .023 wire. Even after all the setback modifications, the body will still look stock from the outside.

I moved the little SBC back as far as possible while still being able to wiggle it's distributor past the base of the windshield. The cowl panel goes back on, but is easily removable when the hood is up.

RX-7 transmission tunnels are HUGE! The original tunnel sheetmetal was cut out and moved back 9-1/2", while the seat brackets were moved back 6". Seat sliders were also removed and the seats lowered as much as possible, making more head room for a helmet. The shifter is now closer to the driver...making it easier to reach 3rd while being pressed back in the seat. The original molded carpet still fits with slight alterations.

The added side seal panels are made from 18ga cold rolled steel sheet. The stock firewall sheetmetal is still there, just moved back a bit in the center for "valve cover clearance". The stock RX-7 pedal assembly was spaced back away from the firewall using 7" long aluminum spacers and uses extended pushrods...

I made a tunnel for the steering column, then added 7" including universal joint to the steering shaft itself. The steering shaft retains it's collapsible feature. The above pic shows the lightened dash understructure before the stock cover was added.

Here's a pic w/ the stock cowl panel installed. With the right intake and carburetor, this could all fit under a stock flat hood...

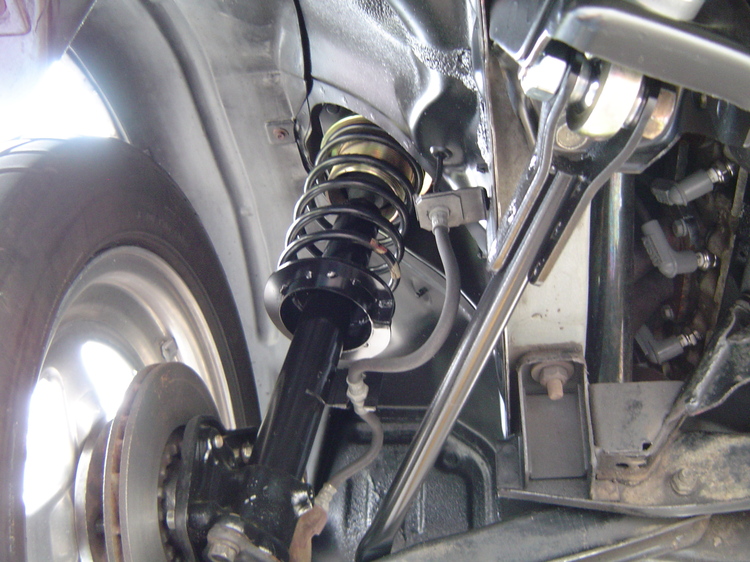

Here's a view of the old front suspension we were using before the engine setback. It has fabricated lower spring seats and adjustable upper seats to allow using stock 101lb/in RX-7 rear springs on the front. The stock front rubber strutrod bushings were converted to rod-ends to reduce binding and increase travel as the frontend rises. The upper strut chassis mounting points were also spaced away from the body 2" to gain even more travel.

Moving the engine back now reveals the RX-7's ugly stock front crossmember. Since the crossmember no longer supports the engine, I made a lighter weight tubular version that is much more appealing, and now doubles as a radiator mount. I also re-did the lower control arms to a lighter tubular version that is 3/4" wider to get better frontend alignment with all the added travel...

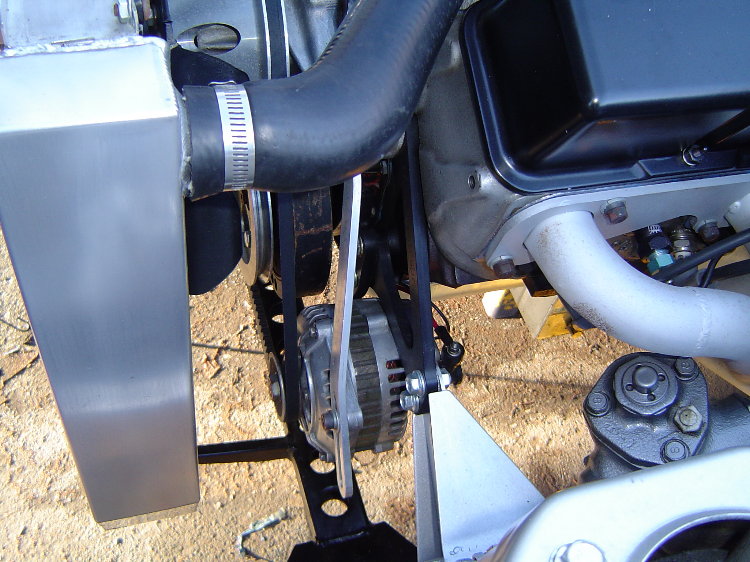

The new tubular front suspension components I made are quite a bit lighter, and use kevlar lined rod ends rod ends at the pivot points. The new strut bars feature tubular aluminum (originals were solid steel). I used an RX-7 alternator, mounted below the motor plate.

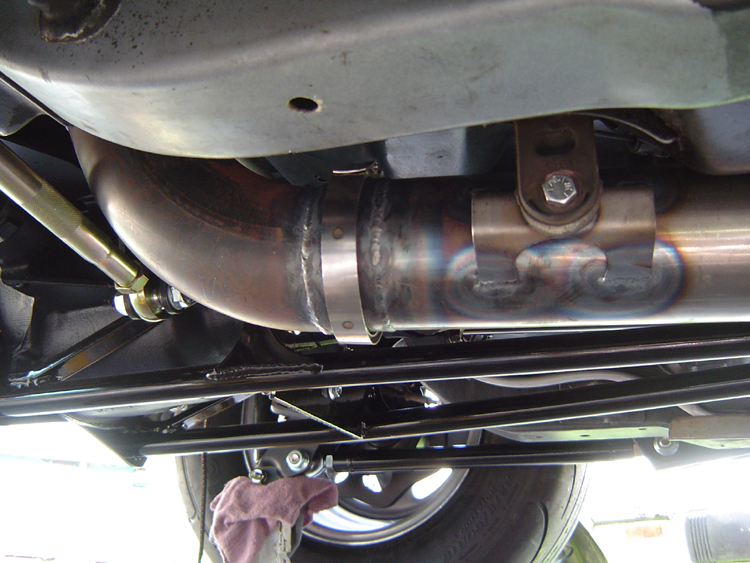

I routed the exhaust pipes out of the side of the extended collectors, and made some caps for the collectors themselves. Now when i uncork the pipes, it flows straight out the collector, not out the side thru a dump pipe. I made some short collector extensions that I add which feature a "tongue" that extends up into the collector to seal off the rest of the exhaust system, making the collectors more effecient. V-bands were used on the mid-pipes to make transmission/clutch maintenance easier.

The car now weighs 2330lbs (2530lbs including a 200lb driver), about 325lbs lighter than last year, even though it still has original glass, stock seats, a full exhaust system and the Huge Magneflow muffler. Depending on fuel load and rear bumper weight, front/rear weight distribution varies between 47/53 and 43/57.

The ignition boxs and coil are now inside the car, behind the firewall. The new radiator mounting could not get much simpler or lighter, possible because now the engine is mounted directly to the chassis (no rubber). I may build a carbon fiber duct between the radiator and nose, but it runs cool just like this. Even in 98 degree heat, it still idles at 185 degrees.

Here's a pic of the outside of the car. No roll bar or cage, no added chassis stiffeners, just an RX-7 built for fun on the street...and a random test-n-tune or grudge night here and there. It's never been on a trailer as long as I have had it, and gets driven everywhere it goes. Under the rear is a narrowed 8.5" GM 10 bolt w/ a Detroit TrueTrac diff and 3.73 gears, as well as adjustable shocks and one of our torque arm suspensions.

I told ya it was still going to look stock when it was done! I need to add power windows now, as the setback dash now covers the window cranks (the doors must be opened to roll the windows up/down). With the exception of the firewall and trans tunnel mods, the car pictured here has a completely stock body- no wheelwell trimming, no mini tubs, no subframe connectors, no roll bar, and no chassis reinforcements. All upgrades are bolt-ons, including the rearend/Torquearm upgrade. The only (2) additional holes have been drilled in the car, in the top of the transmission tunnel, for anchoring the Torquearm's front yoke assembly. Even the hangers for the exhaust system were made to use existing holes in the chassis.

I still need to make a few extension panels to cover the area between the cowl and dash. The carpets are also getting re-dyed, and should be re-installed shortly. The little black knob ahead of the driver's door opening is the adjustable prop valve for the rear brakes.

A gauge panel was made to fill the area where the stock stereo used to reside. It's attached to the support structure under the dash, so when the dash cover is removed, the gauges stay connected and in place.

A 7/8" brake master cyl plumbed to a lineloc and a 3/4" clutch master for the hyd t-bearing.

I changed to a really tall Strip Dominator intake with a 1/2" plate under the carb...the custom made air cleaner base drops the entire aircleaner 3" and almost completely hides the changes. Basically, it keeps the air cleaner at the same height as it was with the low manifold and no plate. It's pretty tough to tell which carb i'm running...my big Holley fits under there, but so does my little carb w/ the tucked in solenoids...

I really like playing the underdog with the little 625cfm Carter. Nobody thinks you're serious when you tell them that's what you have. The little solenoids for the 175 shot are mounted directly to the plate and completely hidden below the air cleaner base. Holley jets (68n, 65f) are pressed into the brass nipples between the solenoids and plate.

Here's a shot of the hood's underside, modified to clear the setback engine location...

Below is the biggest tire that will fit in the stock 1st gen RX-7 rear wheelwells...a 275/60-15 MT "ET Street Radial", DOT legal and measures just a shade over 28" tall. There is about 3/8" clearance at the front and rear of the stock wheelwell opening, so don't try this with a bias ply tire that will grow taller at high speeds. Clearance between the inner sidewall of the tire and inner fender is close at about 3/8", what we would consider the absolute minimum for a car that still has some body roll. The 275/60-15 Drag Radials are on 15x8 Weld Prostars with 5.5" of backspace. The 8.5" 10 bolt GM rear axle has been narrowed, and measures 58" wheelflange to wheelflange with the brake rotors/hats installed. The front wheels/tires are 15x3.5" Weld Prostars with 1.75" of backspace. Stock RX-7 front hubs were re-drilled to 5 on 4-3/4" to match the rear.

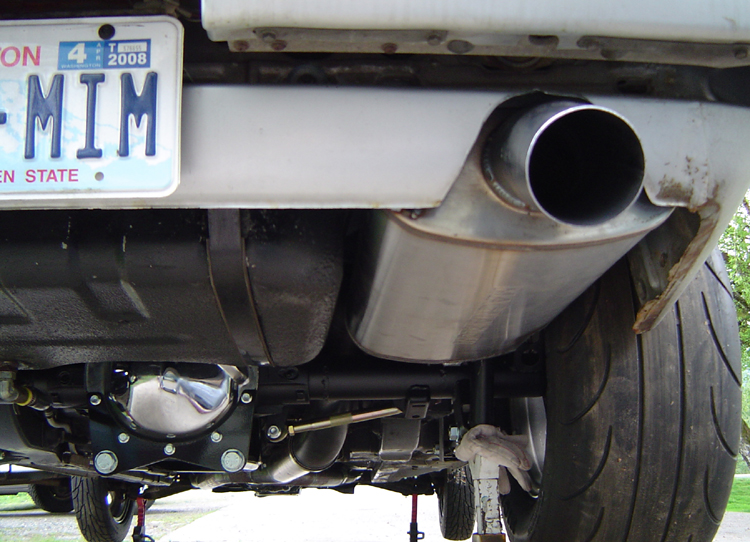

The entire exhaust system is hung with (4) stock RX-7 rubber hangers, 1 here before the axle, and 3 around the muffler. The sheetmetal bracket serves to isolate the rubber from the full heat of the pipe.

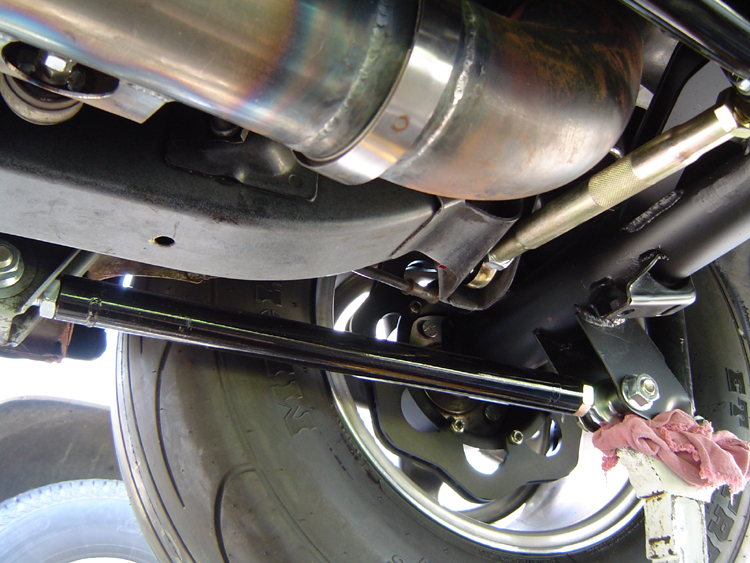

Here's a shot of the Torque Arm Suspension in the car. The nose of the TA is actually anchored up in the top of the tunnel with 2 huge rubber pucks. The shackle plates that connect the nose of the TA to the anchor assy do double duty as a driveline loop. The equal length exhaust merges into a single 3-1/2" pipe for the trip back to the muffler.

The 3-1/2" pipe fits up and over the axle with plenty of room...

Here you can see the adjustable lower links...

Everything tucks up pretty tight...no ground clearance issues...

The giant Magneflow muffler had to be notched to clear the RR tire...

This picture was taken at a short 1/8mi track set up on the front straightaway of a paved oval. 5.73 and a 1.304 60' thru the muffler on a 30 year old surface. Just a fun "no trailer" street car on pump gas, street legal tires, driving down the freeway to a track 2 hours from home. At 2335lbs w/ 3.73 gears it easily cruises down the freeway, just don't forget to bring along a helmet!

Here's what's left of one of a stock block 406 after it blew out #3 cylinder wall at 7300. You could see the cam from outside the engine...