'85 RX-7 Street Car

CLICK HERE for 2010 updates

Here's the RX-7 fresh back from the races with a cowl hood installed. I've had quite a few race cars, but this car is more fun. It can be driven anywhere, at any time. No trailer, no tools, no extra tires...just bring a helmet.

It's still somewhat of a sleeper, and retains a completely stock shell. Everything I did to this car could easily be transferred to another car, as all mods are simple bolt-ons. Hard to tell that I added 90lbs inside that rear bumper.

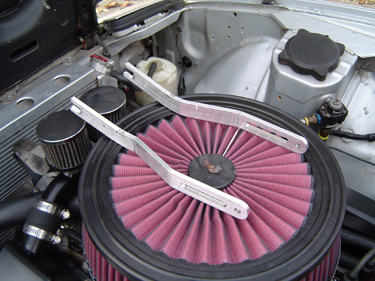

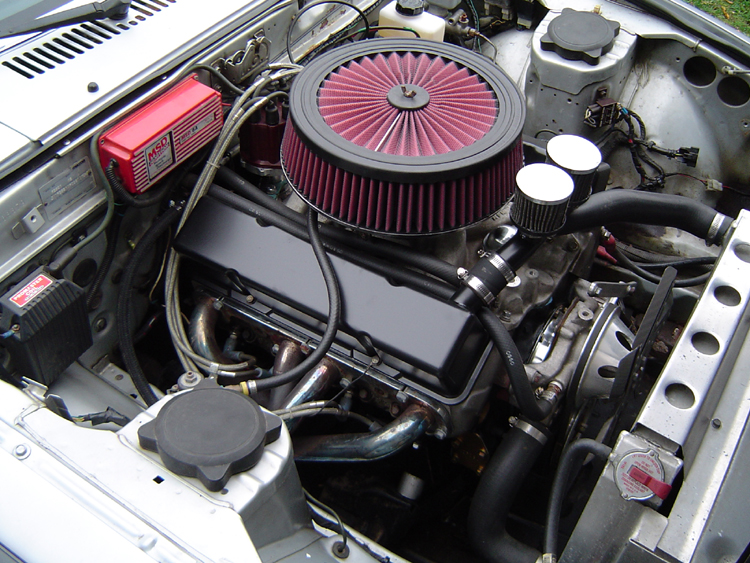

The hood is a lightweight lift-off version that I converted for use with the RX-7's existing hood hinges. I machined a few threaded aluminum spacers to set the hood off of the hinges the same amount as the stock hood. Then made a fixture to locate the spacers in the correct locations, cut some grooves and notches so that the fibreglass could really grab them, then fibreglassed them on. At the rear, I used custom made hood pins that installed into existing holes that were formerly used to locate the rubber bumper pads in the rear corners. I am making a tray to fit under the air cleaner to seal it to the hood for a true cold air set-up.

The car pictured here has a completely stock body- no wheelwell trimming, no mini tubs, no subframe connectors, no roll bar, and no chassis reinforcements. All upgrades are bolt-ons, including the rearend/Torquearm upgrade. The only (2) additional holes have been drilled in the car, in the top of the transmission tunnel, for anchoring the Torquearm's front yoke assembly. Even the hangers for the exhaust system were made to use existing holes in the chassis.

This is the biggest tire that will fit the stock 1st gen RX-7 wheelwells...in this case a 275/60-15 MT "ET Street Radial" that is DOT legal and measures just a shade over 28" tall. There is about 3/8" clearance at the front and rear of the stock wheelwell opening, so don't try this with a bias ply tire that will grow taller at high speeds.

Clearance between the inner sidewall of the tire and inner fender is close at about 3/8", what I would consider the absolute minimum for a car that still has some body roll. The 275/60-15 Drag Radials are on 15x8 Weld Prostars with 5.5" of backspace. The 8.5" 10 bolt GM rear axle has been narrowed, and measures 58" wheelflange to wheelflange with the brake rotors/hats installed. The front wheels/tires are 15x3.5" Weld Prostars with 1.75" of backspace. Stock RX-7 front hubs were re-drilled to 5 on 4-3/4" to match the rear.

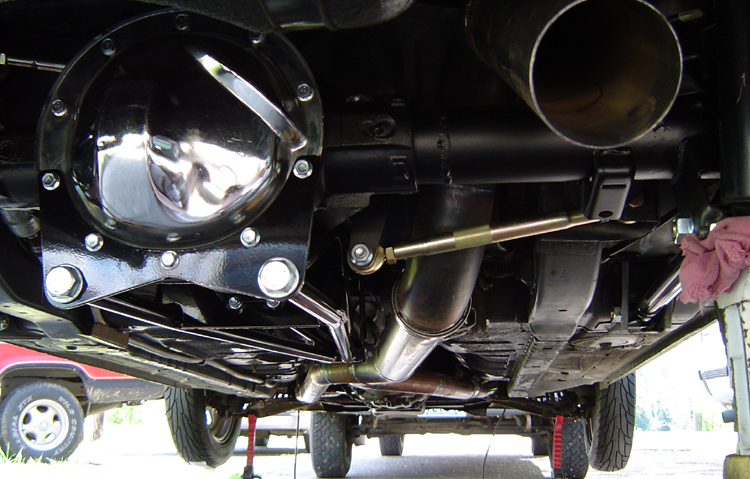

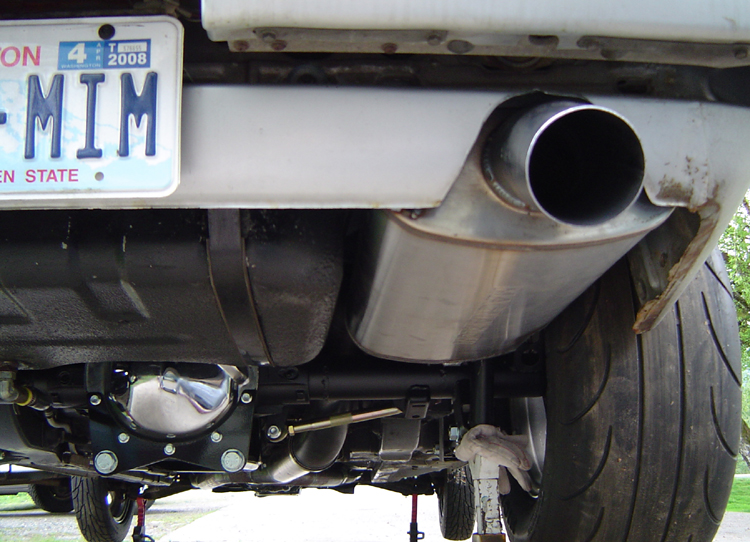

This shot shows my TorqueArm suspension conversion installed, along with the equal length/merged single exhaust system.

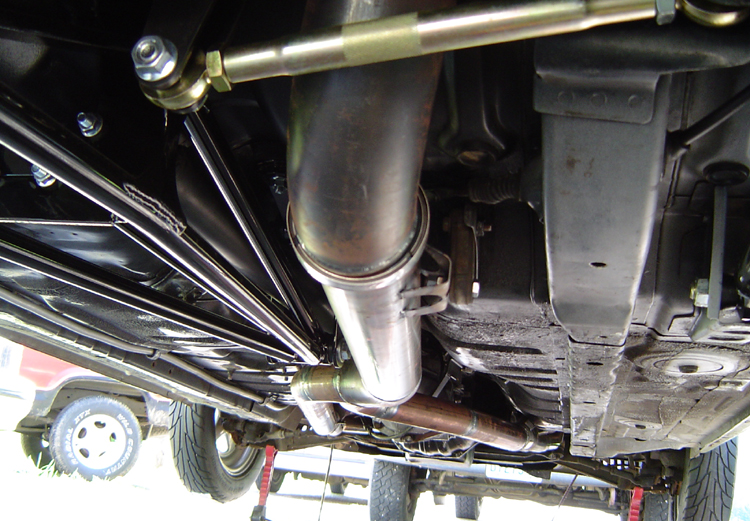

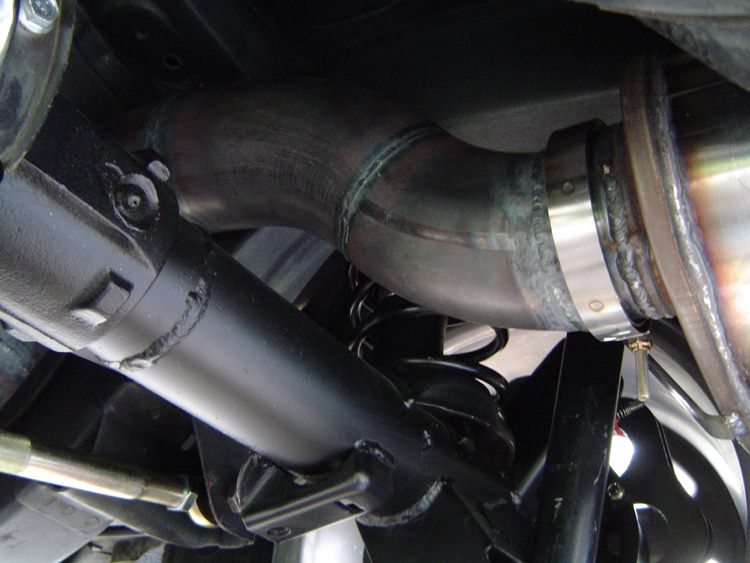

I sent (2) equal length 2-1/2" pipes from the collectors, and merge them into a single 3-1/2" pipe. FYI, two 2-1/2" pipes have about the same cross sectional area as a single 3-1/2" pipe, but the single 3-1/2" pipe has only about 60% of the surface area (less surface friction). It still has all the lope of a Harley at lower RPMs, but at full throttle, it has a smooth hi frequency scream like an Indy car (not to mention that single exhaust/muffler is quite a bit lighter than true dual pipes/mufflers). Some that hear it at the track ask if it has a rotary engine...

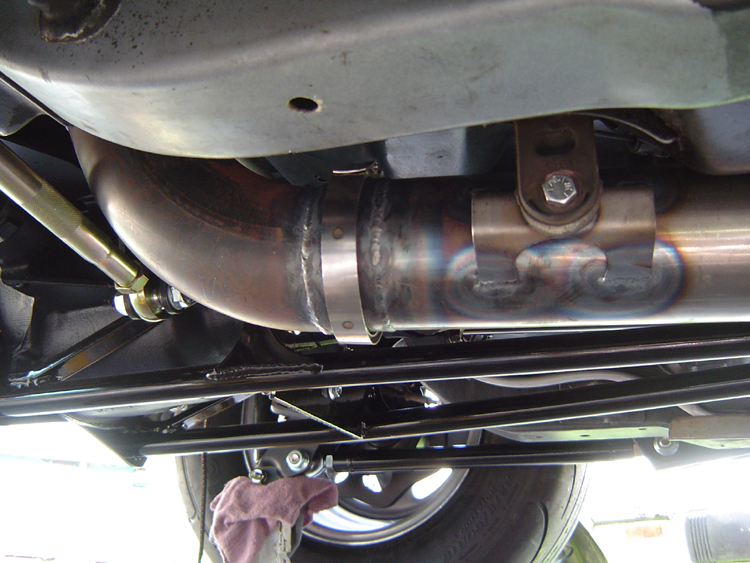

The lowest point of the exhaust system is only 1/2" below the stock 1st gen RX-7 "frame rails", giving excellent ground clearance when switched to "road race" mode. V-band clamps are used to allow quick and easy changes during test sessions.

The entire exhaust system is hung with (4) stock RX-7 rubber hangers, 1 here before the axle, and 3 around the muffler. The sheetmetal bracket serves to isolate the rubber from the full heat of the pipe.

I merged the pipes directly under the driveshaft's tube, the point of maximum clearance just to the rear of the u-joint.

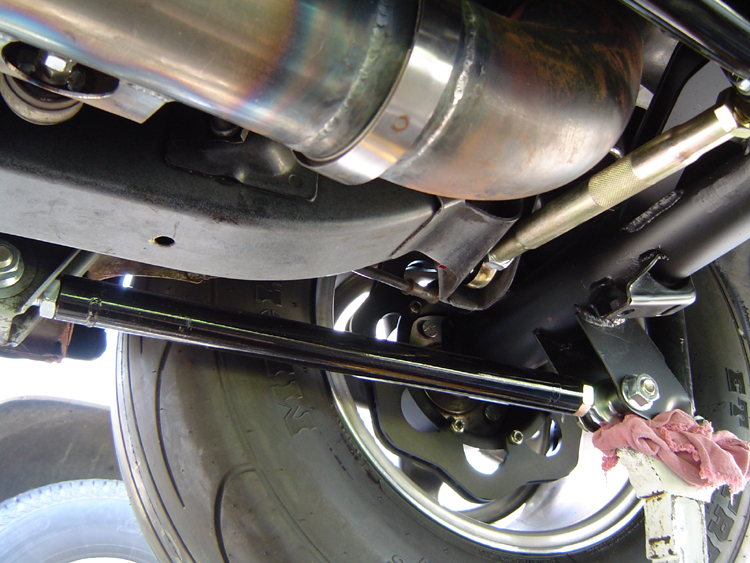

Here's a shot of the clearances around the fabricated watts linkage. The 3-1/2" pipe goes up and over easily, with at least 1/4" of clearance at all points, even with the suspension compressed.

Here you can see the large rod-end style lower links installed. This car also has brackets installed on the rear axle tubes for upper links, allowing us the option of removing or dis-connecting the TorqueArm and going back the stock RX-7 upper links, enabling back-to-back comparisons if needed. I'm also experimenting with using the former upper link chassis brackets as anchor points for brake floaters for the rear calipers, which enables me to eliminate or adjust rear brake hop, making the TorqueArm suspension much more roadrace friendly.

I had to enlarge the exhaust cutout in the rear valance panel. It's pretty easy to do with both right and left-hand tin snips. The muffler is tucked up along side the gas tank, almost completely hidden from view.

This is about the biggest Magnaflow muffler that I could find. It's 3-1/2" offset in, 3-1/2" center out, 11"x6"x22" oval and weigh a whopping 20lbs. Looks like something that belongs on a Diesel truck. I also installed a smaller 14.5 gal fuel tank from a '79 car and also added a 1/2" bottom outlet. The '85 originally came with a 16.4 gal tank.

This thing is so big that I had to use 3 hangers and notch it for tire clearance.

A v-band clamp is used here, allowing me to change mufflers easily. I currently have 3 options back here...

...1- Super quite Magnaflow

...2- Custom 2 chamber Flowmaster

...3- Dump pipe (no muffler)

I use the Magnaflow most of the time, as it attracts the least attention, scares less people, and is less likely to generate a police report. I do a lot of our testing on local country roads, and like to stay as discrete as possible.

As a tuning aid to help quantify your efforts, I recommend using the Gtech Pro SS (available from Summit or Jegs for around $199). It can record up to 30 runs at a time, which can be downloaded to your PC for comparison. It will do all the horsepower/torque calculations, 60', 1/8mi et/mph, 1/4mi et/mph, 0-60 etc, but more useful are the RPM, speed, and "G" run comparison graphs. Make a change on a run and choose a previous run to compare it to, laying one over the other. Up to 4 runs can be compared at a time, making it very easy to see where gains or losses occurred. All that's required to get launch info is at least a 60' run, making it possible to gain useful tuning info without exceeding the speed limit. Does one tire work better than another? Did dropping to 12psi really help? Stiffer or softer on the shocks? find out quickly and easily, without going to the track, with a Gtech.

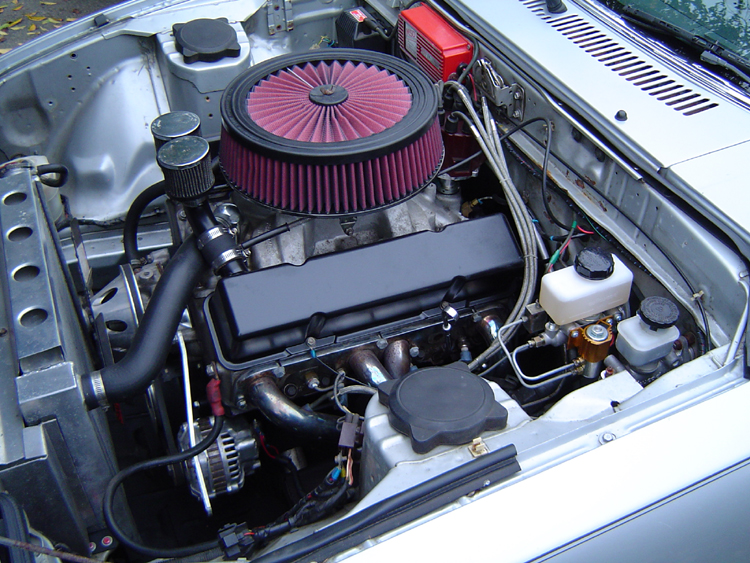

This car was built mainly as a street fighter/test bed. It is completely street legal, retaining heater, wipers, lights, full stock interior and real glass. Driven everywhere it goes, it's never been on a trailer as long as I've had it. Power comes from a flattop 357 Chevy attached to a non-world class 6cyl T5 from a Camaro/Firebird. The engine has an Edelbrock Performer/Carter 625 carb along with 1-5/8"x2-1/2" headers, and runs on a strict diet of common pump gas. The solid roller provides .657" lift, 268/275 duration, on 106 lobe centers. Completely NA, no power adders at all. A 17lb SFI steel flywheel, Ram pressure plate, and stock lining on an Advance Adapters disc inside a liteweight stock aluminum bellhousing. Completely stock un-molested body and wheelwells, no rollbars or mini tubs. The car weighs 2720lbs, including a full tank of gas and a 200lb driver. The narrowed 8.5" 10 bolt GM rear has a PowerTrax locker in an open carrier, and is fitted with 3.73 gears. Full exhaust flowing thru a big muffler. In all, a pretty low-profile combination of parts that work pretty well together for their intended purpose. With the small manifold and carb keeping the velocity up, the cam pulls much smoother from the bottom, allowing us to launch at lower RPMs without creating a traction killing power surge. On the street, typically launched at around 1000-1800rpm depending on conditions, it's good for mid 10s at around 130mph. Even without a burnout and on a common unprepped asphalt road, it is still good for 105mph in the 1/8mi with a 1.8 60'.

I also have an optional rear bumper with 95lbs of lead added to the inside, completely hidden. The stock RX-7 bumpers attach from the outside using 2 simple "pin" bolts, easily accessible from the bottom side thru two round holes in the underside of the bumper cover. The bumpers take only a few minutes to change, but the added weight requires us to add spring shims to the rear springs to retain the same ride height. Removing the rear springs to add the shims requires jacking up the car and removing the lower shock bolts for access, a process that takes about 10min to complete. On an un-prepped surface, the added 95lbs reduces the 60' to around 1.69-1.71.

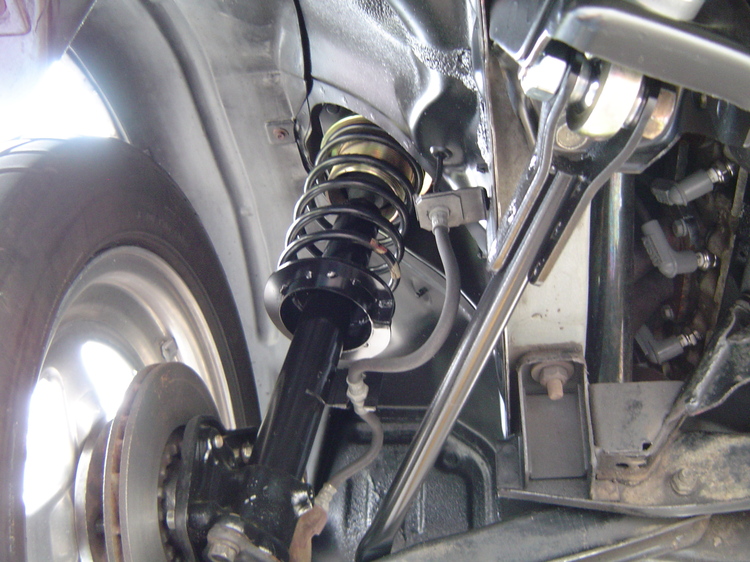

From here you can see a few things I did to save weight up front...I made a plate to convert to manual brakes (no more brake booster), eliminated the headlight motors, and removed the front sway bar. The plastic 2nd gen covers on the top of the strut towers hide the fact that the upper strut mounting hardware has been spaced 2" away from the underside of the tower, allowing the front of the car to rise higher under acceleration.

For the trip back home after the races, I made a couple of liteweight aluminum straps that I can quickly install that serve to hold the headlights in their upright position. They attach to the lower stud that formerly held the headlight motor in place, using a wingnut for installation...no tools required. A functioning heater is also nice to have on the way home, no need to keep wiping the fog from the windshield.

The car used to have a T5, but 3rd gear wouldn't last below 6.90 in the 1/8th. I really miss that overdrive on the freeway.

My favorite metal skull shift knob was hollowed out and fitted with a switch for the lineloc. The momentary switch came from Radio Shack, 2 to a pack, for a few bucks, as did the 14ga hookup wire. A large deep hole was bored up from the rear of the skull's base for the switch. A smaller hole was drilled up in the front under his chin, deep enough to meet the rear hole at a point above the shifter threads. Wire was fed in from the chin hole, up over the threads, and out thru the large rear hole. The ends of the wires were then soldered to the switch. Before pulling the wires back thru to seat the switch, the interior cavity was filled with silicone, which provides protection against an internal short. After the switch was seated, the wires were tested to make sure the switch was working and that there were no shorts. After that, a 2 pole "Dean's Connector" (get 'em at the RC shop) was added about 6" below the switch (below the boot) so that the wires can be quickly disconnected when the shifter or transmission are removed. The little Deans Connectors are great, ultra lite and good for 35amps or more, I use them for fuel pumps and ignition boxes too.

Here's an experiment...I pro-shifted 2nd and 3rd gears in a Saginaw 4spd, then designed a hybrid "rail" style shift linkage to make it fit the RX-7's stock floorpan and console...it requires no chassis or tunnel modifications for installation. The shifter sits up over the center of the output shaft, and fits the RX-7's interior console and boot perfectly. Current updates included replacing the guide plate that attaches to the top of the main case with two lighter aluminum female rod ends located by simple holes drilled/tapped into the top of the case. The Hurst SuperShifter stick was also shortened slightly to put the shift knob in the perfect spot.

Why did I choose a Saginaw instead of a Muncie?..available 1st gear ratio to go along w/ the 3.73 rear. The Saginaw has a 3.50 1st gear vs the Muncie's lowest available 2.52, providing a much better 13.05 overall ratio for launch (the Muncie would provide only a 9.39 overall gear). I really miss the T5's overdrive at 70mph on the freeway, but it became less than reliable whenever 90lbs was added inside the rear bumper. After driving home 85 miles from the strip 4 different times with a T5 missing 3rd gear (thank god for that big magnet in the bottom of the T5), I had to make a change. Another thing to consider is that the Saginaw 4spd is pretty easy to find for around $75.

Going down the hiway in 4th, with the Saginaw we do 2500rpm @ 55mph, and 3175rpm @ 70mph. The T5's 5th gear overdrive knocked the rpm @ 70mph down to 2325rpm. Unless you really need the extra strength, the T5 is a great choice.

I spent several hours cutting and grinding on the cast-iron Saginaw, lightening it up to the point that the complete Saginaw trans/shifter package weighes only 12 lbs more than the all aluminum T5 trans/shifter package that it replaced. The gears are quite a bit wider than those inside the stock T5, and the pro-shift mods I made to the sliders and dog teeth make shifts almost effortless. This is a key point to making the Saginaw live, as it's shift fork design is a bit weak.

The clutch uses a 3/4" Wilwood master cylinder, and a stock RX-7 slave cylinder, mounted on the bellhousing using a fabricated slave bracket. The throwout fork is shortened, and a Lakewood adjustable fork pivot was used to optimize the throwout fork / release bearing geometry. The results are well worth the effort.

The car runs well into the 6's in the 1/8mi using this transmission/shifter, with no failures to date, but i've got a set of dog rings and dog ring sliders for a Top Loader, which will probably go in mid-season.

Any doubt it's a street car?

Updates...

...Changes to the front suspension for the drags...

1...The 1st mod was re-valving the 1st gen RX-7's stock front struts to 90/10. This is only possible with the original front struts, which are rebuildable. Many 1st gens have already been converted to cartridge style strut inserts, which are not suitable for my purposes.

2...The 2nd mod basically allowed moving the RX-7's softer rear coil springs onto the existing front struts. The RX-7's stock front springs are rated at 121 lbs/in, while the stock rear springs were quite a bit softer at 101 lbs/in (12-3/4" long). Springs this soft are hard to find in a size that fits the RX-7's strut. What I have done is make a set of spring adapter seats to make the switch possible. The lower adapter seat simply slides over the strut and onto the existing seat. The new upper seat uses a threaded sleeve and is adjustable, making it easy to get the perfect ride height while using the softer springs.

3...The 3rd mod involved spacing the strut's upper mounting plate down and away from it's 4 bolt chassis mounting point at the top of the strut tower. Normally, the amount of possible change is limited to about 1/2" by the length of the studs on the upper mount. What I have done is to make a set of threaded spacers that screw onto the studs, allowing the front-end to rise up to 2" more during launch.

4...The 4th mod was modifying the front strut rod's front attachment point for more movement. The stock rubber bushings are very restrictive, actually resisting full suspension drop. I converted the strut rod's front bushings to rod-end style connections, allowing an almost unlimited range of motion.

5...Added adjustable tie-down straps to the front suspension.

...Changes to the rear suspension for the drags...

Besides converting to our Torque Arm rear suspension, I also made the following changes...

1...The first change involved extending the rear bump stops. This mod allows using the largest possible rear tire in the stock wheelwell, and prevents it from contacting the fenderwell's lip.

2...The second change is a new threaded/adjustable upper spring seat. This makes it easy to maintain the perfect rear ride height while changing spring rates and adding/removing ballast.

3...The third change was moving back to the softer rear springs.

......if you have stock front shock valving (poor weight transfer)...we suggest 175lb/in(slick track) or 225lb/in (good track)

......if you have 90/10 front shock valving (good weight transfer)...we suggest softer 100lbs/in (stock rate was 101lb/in)

4...The fourth change was to install adjustable rear shocks.

5...The fifth change was to add a stiffer rear sway bar. With the tires almost completely filling up the rear wheelwells, excessive body roll due to soft springs and no front sway bar is not a good thing. For this car, I heated and slightly re-bent a rear sway bar from the rear of a Crown Vic. The larger diameter bar required re-using the rubber mounting bushings from the RX-7's discarded front bar, but the bar was nearly a direct bolt-in.

CLUTCH UPDATE...I am now using a ceramic lined/solid hub clutch disc. This is completely counter-intuitive from my goal of trying to keep the car hooked to a slick track (street racing), but here's why we think it works...

#1- this car's ability to put down power is closely matched to the power it's engine makes.

#2- yhe light flywheel allows the track to "work" the engine, making the combo more compliant.

#3- the lite solid hub "puck" style disc makes shifting quicker, and less damaging. No marcel means quicker/cleaner dis-engagement. Lighter overall disc weight means less inertia is available to damage the sliders/dogs when the trans is slammed into the next gear.

I also modified the two of the Saginaw's neutral detent ramps. They are now much steeper, requiring more effort to exit neutral when entering 2nd and 3rd (the pro-shifted gears). The result is that, when shifting into these pro-shifted gears, if you apply enough pressure to exit neutral, it now pops completely into engagement. No more accidently grinding the gear by not shifting aggressively enough. The transmission now requires much less maintenance.

The Saginaw's input shaft pilot was worn a bit undersize, but instead of throwing it away, I machined a custom pilot bushing from Delrin plastic (couldn't find any bronze big enough on a sunday). I was a bit skeptical at first, worried that the plastic might melt from the clutch heat. No problems though, to date it has worked flawlessly.

With the above changes, it went from 6.80 to 6.40 timeslips. Please keep in mind that the engine has not changed at all for the timespan of this entire webpage, the valves have not even been adjusted in about 7 years. Same solid roller cam, same heads, same intake and 625 Carter carb, same rear ratio and wheel/tire sizes. The only changes have been to the suspension and clutch/trans.