The clutch's engagement characteristics and consequently how fast the clutch pulls the engine down during launch, as well as after the shifts, are among the most important adjustments you can make to a stick shift drag car. Torque x RPM, highest average number wins if you can get all that power to the track consistently. Raising launch rpm adds area under the engine's rpm trace, which means the engine will produce more power strokes in a given time frame. But what happens after the shifts can also add area under the engine's rpm trace.

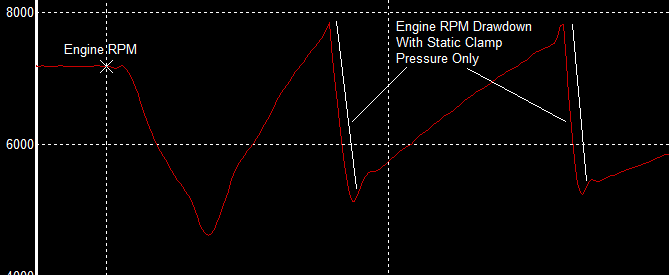

With the typical diaphragm, B&B, or Long style pressure plate (spring pressure only, no added centrifugal assist), the drawdown part of the engine rpm trace after the shift will be pretty linear, basically a straight line like on this graph below...

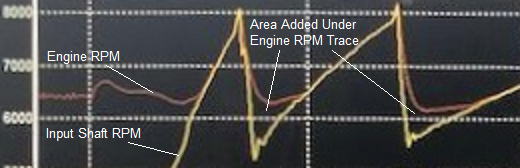

With a SoftLok style "adjustable slipper clutch" that uses counterweights in addition to spring pressure to clamp the disc, the drawdown part of the engine rpm trace will form a gradual curve. Because the centrifugal counterweight component relaxes as the clutch pulls engine rpm down, overall clutch clamp pressure relaxes as well. Note that engine rpm initially drops very quickly after the gear change (trace falls almost straight down initially), but then the trace begins to curve as the clutch gradually loses it's ability to pull the engine down any further...

An advantage of the curved engine rpm drawdown shape after the shift is that it adds area under the engine's rpm trace (more engine power strokes in a given time frame). If the clutch had not slipped at all after the above 1/2 shift, the ratio change dictates it would have pulled the engine down to around 5245rpm (input shaft speed) after the tires hooked back up. But because the SoftLok style clutch has an additional centrifugal component, clamp pressure gradually relaxed as the engine lost rpm, which in-turn gradually slowed down the rpm loss. Because the car was also gaining speed while the clutch was slipping, the delayed lockup point raised the minimum rpm after the shift to 6302 instead of drawing the engine all the way down to 5245rpm as predicted by the ratio change. That added clutch slip time effectively tightens up the engine's operating range, which in-turn allows the engine to operate higher on the plateau of its HP curve.

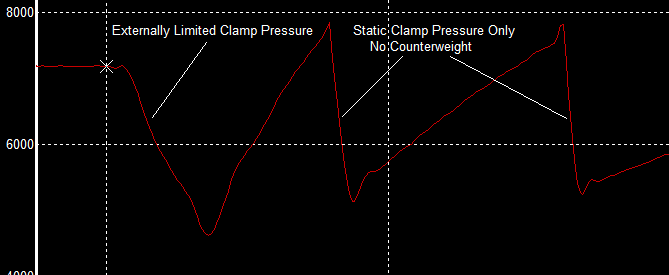

Going back to the static-only (no added centrifugal assist) straight line clutch graph, it's important to know that you can adjust the angle of engine rpm drawdown after the shifts by adjusting the clutch's static clamp pressure. Note on the below graph that the angle of drawdown after both shifts are basically the same, while the drawdown after launch is still straight but the angle is different as launch rpm was drawn out over a longer time period...

The above difference between launch and after shift drawdown angles was made possible by externally controlling throwout bearing position during launch. Basically the throw-out bearing was not allowed to fully retract during launch, which prevented the full force of the clutch's spring pressure from clamping the disc. The throw-out bearing was then allowed to retract shortly after launch, which in-turn increased the clutch clamp pressure available for the shifts. The angle of drawdown during launch is adjusted via throw-out bearing position, while the angle of drawdown after the shifts is adjusted via static clamp pressure. In the end you end up with more clutch slip during launch, and less clutch slip after the shifts.

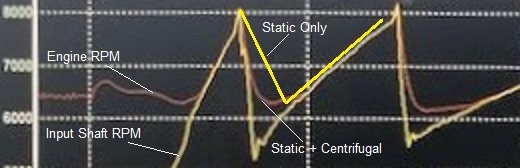

Here's the SoftLok style curved drawdown shape compared to what the "static only" straight drawdown could look like if static clamp pressure were optimized. Notice how the "static-only" (no centrifugal assist) straight-line drawdown angle can be optimized to add even more area under the engine's rpm trace than the traditional SoftLok style curved drawdown. Also note that the initial drawdown after the shift is not as steep. That flatter angle indicates energy is leaving the engine's rotating assy at a slower rate initially, which in-turn makes it easier to keep the tires stuck thru the shift. Because the engine is producing power at a quicker rate during the optimized "static only" straight-line drawdown, the clutch lockup point occurs sooner, which then allows the engine to get a head start on its climb to the next shift point...

When you add external throw-out bearing position control to the "static only" (no centrifugal assist) straight-line drawdown, it allows you to take advantage of much higher rpm launches without knocking the tires loose. That adds even more area under the engine rpm trace without dragging the engine down. The resulting high rpm dead hook launch really shines on a crappy track, it also reduces the need to adjust tire pressure and launch rpm for the purpose of controlling wheelspeed. Without the need to control wheelspeed, you will likely be able to make use of less first gear ratio, which will in-turn allow tightening up the gear splits if that is an option for you. Little gains here and there, but it all adds up.

In the end its much like a quick automatic transmission car. A less efficient coupling (converter) allows the engine launch higher and gain rpm faster, while also reducing rpm loss after the shifts. The increase in power production shows up as more area under the engine rpm trace, and that added power production more than offsets the loss of mechanical efficiency.

In my opinion, in most cases the traditional "adjustable slipper clutch" style centrifugal assist clutch tune is becoming outdated tech. First it limits your ability to take advantage of launch rpm, then it has a tendency to knock the tires loose after the shifts. Knocking the tires loose after the shifts is usually what prevents guys from making the switch to radials. Even if you have a modern ECU that allows momentarily reducing power to absorb the spike after the shifts, those momentary power reductions will still cost you ET vs a properly adjusted "static only" clutch that needs minimal or no power reduction after the shifts. Combine that with the ability to raise launch rpm by controlling throw-out bearing position during launch, the adjustable centrifugal assist feature in most cases becomes obsolete.

CHANGING THE GAME ON LAUNCHING YOUR STICK SHIFT CAR!!!