HitMaster In-Line Hydraulic 2-Stage Clutch Hit Control System

A QUICKER, EASIER, and MORE CONSISTENT WAY TO TUNE YOUR CLUTCH!!!

HitMaster In-Line Hydraulic 2-Stage Clutch Hit Control System

A QUICKER, EASIER, and MORE CONSISTENT WAY TO TUNE YOUR CLUTCH!!!

It's also important to note that the more rigid your clutch assembly is, the more critical the overall precision of your clutch control system will be. In some applications just a few thousandths variation in throw-out bearing position during launch can have you chasing your tail instead of making progress.

WHAT MAKES THE HITMASTER THE MOST ACCURATE HYDRAULIC CLUTCH HIT CONTROLLER AVAILABLE?

Here are some external variables that have ZERO affect on the accuracy of the Hitmaster, but can affect other clutch control systems...

The Hitmaster is very easy to dial in...

The Hitmaster does have one other thing to adjust, that's when the system shuts off which in-turn allows the throw-out bearing to fully retract. Typically set to happen around 0.80sec out or around 20mph, this function can be controlled by either a button activated timer or a mph switch function programmed into an ecu. Exact timing of when this transition occurs is not critical to performance, as by that point in the run the clutch should either be already locked up or very close to it.

Is reaction time important to you?

The Hitmaster can also greatly improve your consistency against changing track conditions. If you dial it in for a no-bog dead-hook launch on a poor surface, then your results won't change much if the surface improves.

Some more experienced racers wish they could change the clutch setting before staging, depending on what they see on the starting line. With the Hitmaster, just reach over and turn the knob without removing your gloves.

Plumbing the Hitmaster system...

The key to the Hitmaster's high level of accuracy is the Hitmaster valve's adjustable-stroke in-line metering piston (provisional patent application for this feature was submitted back in April 2019), which directly limits how far the throw-out bearing can retract during launch. With a direct hose connection between throw-out bearing and metering piston, there is no needle-valve/orifice/solenoid in the way to slow reaction time. Basically if the Hitmaster's metering piston stroke is set to allow 4.92cc of fluid return in the Hitmaster's 1st stage mode, EXACTLY 4.92cc of fluid will return during launch regardless of any external variables. Precision return fluid volume control is especially critical in small clutch / big power combinations, it's why some of the quickest/fastest stick-shift FWD/AWD cars in the world now use the Hitmaster after trying many other clutch control products.

...fluid temperature/viscosity changes (cold morning fresh off the trailer vs hot afternoon hot lapping)

...how fast you pull your foot off the clutch pedal (tired at the end of the day or excited trying to cut a good lite?)

...system pressure changes (amount of clutch lever/finger centrifugal feedback pressure which varies with launch rpm)

...accuracy/precision of a trigger switch and it's installation geometry/adjustment

Once again, these external variables have ZERO affect on the throw-out bearing placement accuracy of the Hitmaster!

...if the tires spin or the engine bogs during launch, turn the adjustment knob clockwise (reduces metering piston travel distance)

...if the clutch slips too much during launch, turn the adjustment knob counter-clockwise (increases metering piston travel distance)

When you dump the clutch with the Hitmaster, fluid returning from the throw-out bearing or slave is not slowed down by any sort of restriction/orifice/solenoid like it is with other systems. A restriction might not be a problem if your track uses a full tree, just dump the clutch earlier. But on arm drop, flashlite starts, or even a pro-tree, any sort of delay in the clutch hit can be a problem!

When plumbing the Hitmaster system, be sure to use PTFE lined hoses. Exact length of the hoses needed depends on where you choose to mount your Hitmaster valve and transition valve. Imports generally use smaller ~5/8" master bores and are fine using -3 fittings/hoses, while domestics typically use 3/4" and larger masters that are better suited to using -4 fittings/hoses. AN fittings are basically the same as JIC as far as sealing geometry, so it's pretty common to see mixing/matching of the two in an automotive application. JIC spec fittings and hose ends are typically made of steel and are generally less expensive than the typical anodized aluminum AN counterpart. JIC fittings can be found along with PTFE lined hoses at suppliers such as Summit Racing or local hydraulic supply shops.

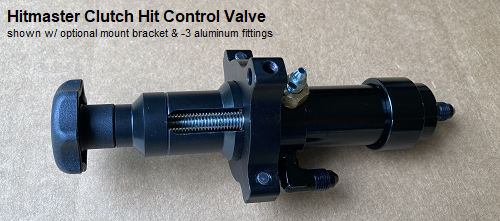

HitMaster Clutch Hit Control Valve (1/8npt fluid ports).........…...…….…$319.

2nd Stage Transition Valve (1/8npt ports, appx 2.25a @ 14v)..........…...$119.

1st to 2nd Stage Transition Timer (12v)...….............................................$39.

Priority Mail Shipping to a destination within the USA.......................add $18.

UPGRADE OPTIONS

......Option 1- Clamp Style Black Anodized Mounting Bracket..................$39.

......Option 2- Shifter Mounted "Launch" Trigger Button............................$19.

......Option 3- LED 1st Stage Indicator Light...............................................$9.

......Option 4- Steel -4 Fitting Upgrade...…................................................$39.

......Option 5- Black Aluminum -3 or -4 Fitting Upgrade...…......................$69.

ORDERING INFORMATION "CLICK HERE"

QUESTION- What makes the Hitmaster better than the other manual transmission "launch controllers" on the market?

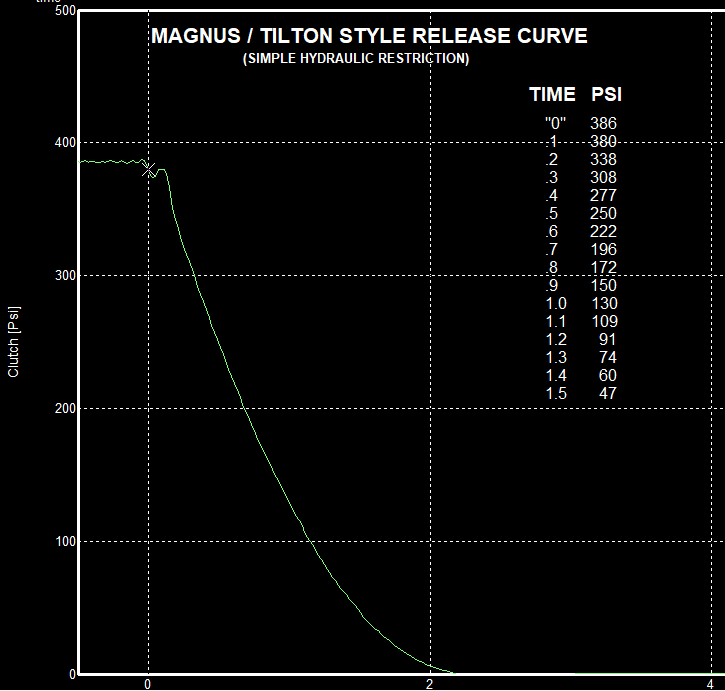

ANSWER- Here's what TOB pressure release curves look like when using Magnus/MAP/Clutchmasters/Tilton style simple hydraulic restriction to control the clutch's engagement speed...

>

>The sweet spot for the clutch is that zone between too much bogging and too much spinning. For this hypothetical example, let's say the car's sweet spot zone for a launch "hit" is somewhere between 200-125 psi at the TOB. The graph above shows it takes 0.686 sec from clutch pedal release for this example's TOB to reach 200psi.

The common fix for that launch delay is to "pre-load" the clutch/drivetrain with the clutch pedal. Let's say you can pre-load the TOB down to 300psi before the car pushes thru the beams. Even with that 300psi pre-load prior to launch, delay time from 300psi to the beginning of the 200-125psi sweet spot zone is still .362sec. That delay makes the clutch slow to hit the sweet spot, but then it only spends 0.334 in that sweet spot zone before dropping below 125psi. Long enough to stick the tires, but not long enough to prevent a mild engine bog.

If you increase the restriction size to reduce the delay time, pressure at the TOB will drop past the sweet spot zone too quickly, causing the car to slow down due to too much tire spin or severe engine bog. Basically the size of the hydraulic restriction becomes a compromise between launch delay and bogging/spinning. The hit ends up both lazy and not lasting long enough, but it's still far more consistent than trying to ride the sweet spot zone with your foot.

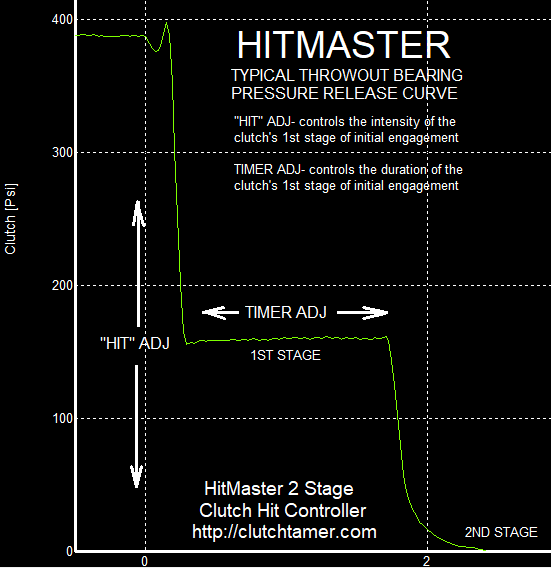

Here's a graph of our Hitmaster's typical TOB pressure release curve...

The Hitmaster responds as quickly as you can remove your foot from the clutch pedal, with no added delay. It's adjustable 1st stage hits the lower limit of the sweet spot zone almost instantly for a firm/crisp hit that's just short of spinning the tires, and then you have control over how long the clutch stays there before the 2nd stage kicks in to lock the clutch up. You can't even come close to this release curve shape with the Magnus/MAP/Clutchmasters/Tilton units. The Hitmaster system is basically like having two clutches in one- 1st stage dialed in for the best launch, 2nd stage for holding all the power you can make.

We recently had a customer install the Hitmaster system on his C6 Corvette, he reported five 1.43 60's in a row during his first track session with the system installed.

QUESTION- Can I turn the Hitmaster off for street driving?

ANSWER- If you prefer, you could disable the system by installing a simple toggle switch in series with the trigger wire. That said, there really is no need to turn the system off for casual driving, as the "default" position of the transition valve provides a direct fluid path between the clutch master cyl and the slave. Bottom line is during casual driving, normal clutch operation is not affected in any way unless the launch trigger switch is activated.

QUESTION- Do I engage the line-lock button when I stage, then just release the line-lock button and side step the clutch to launch? If everything is triggered off the release of the line-lock button, how do I use the line-lock for burnouts?

ANSWER-Yep, just release the launch button and side step the clutch to launch the car. Although the system doesn't have to be triggered off the line-lock button, we do suggest it as then a single button can both release the line-lock and also trigger the Hitmaster's transition timer. If you do not have a line-lock or line-lock button, as an alternative you could use one of our shifter mounted switches to trigger the system.

If you want to turn the system off for the burnout, a simple switch can make that happen. Radials usually don't need much burnout, usually just a quick 1st gear hit to clean the tires off. Typically you don't need to turn the system off for a 1st gear burnout with wet tires. But if you need to really heat up a set of bias slicks with a 2nd or 3rd gear burnout, it would be best to temporarily turn the system off for the burnout only. For that we suggest a normally "on" momentary push button switch to interrupt the system's trigger signal, hold the button down to de-activate the system for the burnout only. Using a momentary switch to de-activate the system instead of a simple two position switch eliminates the possibility of forgetting to re-arm the system after the burnout.

QUESTION- Can the Hitmaster be used on a nitrous or boosted car?

ANSWER-That's where the Hitmaster really shines. It can hit deeper in the clutch's sweet spot while still giving you all the slip that you need for launch, and then quickly transition to full clutch clamp pressure to hold the torque of nitrous/boost as soon as the car will take it. That 2nd stage transition point to full clutch clamp pressure is controlled by a simple timer, easy to adjust in 0.01 sec increments.

For nitrous, we generally suggest delaying the nitrous hit until the clutch is almost locked up. If you look at data graphs very long, you will notice that the car actually accelerates at a faster rate while the clutch is pulling the engine down. That's basically due to an inertia boost that you get while the rotating assy is losing some of it's stored energy. Using a nitrous delay allows the nitrous to come in on the heels of that inertia boost instead of adding to it, which in-turn makes overall power delivery much smoother for radials and no-prep surfaces.

QUESTION- How your are installing the two timers to separately control the shifts?

ANSWER- Here's the configuration we suggest for using two timers to make the Hitmaster system also active after clutch assisted shifts-

...Launch timer is triggered off the release of the line-lock button.

...Shift timer is triggered off a pressure switch installed between the clutch master and Hitmaster valve.

Both timers are wired in parallel to the same transition valve. Since the launch timer is set to a longer delay than the shift timer, it's the launch timer that ends up controlling the clutch's transition point after launch. But then since you don't use the line-lock button on the shifts, the shorter duration shift timer ends up being the one that controls the Hitmaster's transition point after the shifts.

QUESTION- I purchased 2 Hitmaster systems a little while back, and have recently installed one into my S550 Mustang. I did not install it myself, a company installed it and I believe they were in contact with you a couple of months ago for advice.

The system is working, although I have yet to test it. I wanted to confirm with you that it is installed and working correctly, this is what is happening when tested with engine off. When I release the clutch, the pedal stops at the desired location adjusted by me. At this point the timer cuts in, and when it times out the pedal quickly fully engages. My concern is there seems to be no transition between the 1st and 2nd stage. The pedal stops at the first point, stays in that exact position for the amount of time put into timer, then fully engages.

I have one of your original ClutchTamers (mechanical version) on another car that I have been racing for over a year… I absolutely love it, I have done 56 passes with zero breakages and have become extremely consistent- 10.78 10.75 10.80 et’s, and I'm enjoying bracket racing again. It's 'Tamer has a transition between the two stages where the pedal slows right down through the sweet spot…. The Hitmaster installed on my S550 Mustang does not, it seems very harsh compared to the mechanical version…. I just wanted your advice before testing it to see if this has been installed incorrectly.

ANSWER- It sounds like the Hitmaster system installed on your S550 Mustang is operating correctly, just add a couple tenths of a second to smooth out the transition. The Hitmaster's 1st stage is only supposed to be active until vehicle speed gets a chance to sync up with engine rpm, which generally occurs about 15'-20' out from the starting line. After that MPH/RPM sync point the clutch is no longer slipping, so the Hitmaster's sudden transition from 1st Stage to full clutch clamp pressure has no affect on traction, adds no shock to the drivetrain, and minimizes wear on the clutch by ensuring the clutch isn't slipping any longer than it needs to.

Basically the clutch needs to stay within your sweet spot zone until the sync point.

With the ClutchTamer, the clutch must hit above the lower limit of your sweet spot zone in order to stay above that lower limit for that first 15'-20'. This is due to the original 'Tamer's gradual gain of clutch clamp pressure after it's hit point.

With the HitMaster, you can hit right at the lower limit of your sweet spot and still not blow thru it before the sync point.

Generally the closer the clutch can hit to your sweet spot zone's lower limit without blowing thru it before the MPH/RPM sync point, the quicker and more efficient the launch will be. Because the HitMaster has the ability to hit deeper within the sweet spot zone, it can typically 60' a little better than our original ClutchTamer. The HitMaster can also get to full clutch clamp pressure quicker after the sync point, making it a better choice for handling the full torque of a power adder.

CHANGING THE GAME ON CHOOSING THE RIGHT CLUTCH FOR YOUR CAR!!!