GSS Torque Arm / Solid Axle Conversion System

(TA/SA conversion)

CLICK HERE to view our on-line TASA install guide

CLICK HERE to view our on-line TASA install FAQ

CLICK HERE to see our 1st gen "shop mule" with TASA and full exhaust

Looking for better mileage? lower engine RPMs? increased reliability? lower 60' times?

UPDATE- Our 8.8 Deluxe Package now come standard with Billet 9" style housing ends and Forged 31 spline 9" style axles- NO MORE C-CLIPS!!!

UPDATE- Our 8.8 Deluxe Package now come standard with Billet 9" style housing ends and Forged 31 spline 9" style axles- NO MORE C-CLIPS!!!

Our TA/SA conversion system now makes it easy to get the rear gear ratio of your dreams. Designed to use existing rear chassis subframe attachment points, our design features 2 lower links and a unique tuneable torque arm design to get the best compromise for both the drag and road racing worlds. Although our system is currently offered for both 1st and 2nd gen RX-7s, a 3rd gen '93-'95 RX-7 version is in the works. Advantages to our TA/SA conversion for the '86-'91 RX-7 are...

...Get the ratio you want...3.08 / 3.27 / 3.55 / 3.73 / 4.10 / 4.30 / 4.56 / 4.88 / 5.13 currently available.

...Same flange/flange width as the '86-'91 RX-7.

...Same 4 on 4-1/2" or 5 on 4-1/2" RX-7 lug pattern w/ metric studs. You can use your existing wheels/tires

...Stock RX-7 rotors and calipers bolt right on...retain your existing e-brake

...New 31 spline Track Lok clutch style locking diff

...New 31 spline forged 9" style axles

...Rear rise instead of squat during accelleration. Lower 60' times / more forward traction from your tires.

...Torque arm design allows body roll during cornering. Ladder bar & most common 4-link designs turn the rearend housing into one huge 3" dia sway bar, completely eliminating body roll, reducing your car's status to "drag-race only". Our torque arm design allows body roll, giving the driver important feedback necessary to perform consistant high-speed transitions.

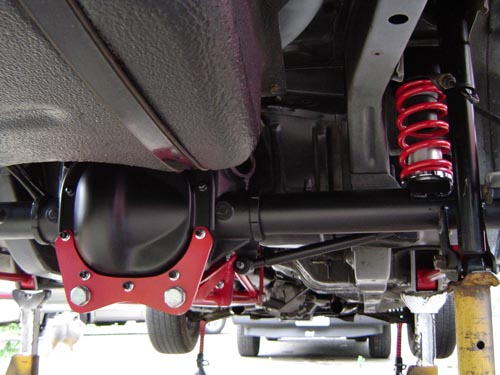

...Use your existing rear springs / shocks. They just bolt directly to our brackets.

...Driveline loop feature included as standard equipment.

Here's some recent initial TASA dragstrip feedback reported by a 2nd gen / SBC customer in Louisiana....

footbrake w/ Turbo 350 (all motor)...10.65 @ 130mph / 1.45 60'

transbrake w/ Powerglide (all motor)...9.75 @??? / 1.30 60'

This car recently sustained extensive damage from a hard landing after carrying the front wheels out past 60 feet. The damage was to the engine's oil pan, stock subframe, and transmission oil pan. The TASA Torque Arm also sustained enough damage from the incident to require replacement. Wheelie bars are now being added. Not too bad for a streetable suspension that can still go around corners.

Major components of the TASA system function as follows...

Major components of the TASA system function as follows...

...Torque Arm Assembly- This is the key component that controls the huge re-action forces of the rear axle, efficiently re-directing that force in a manner to increase rear tire traction during acceleration. We have settled on an effective length of 33" (45" available on request), and prefer to use rubber bushings at the front to help reduce peak impact loads on drivetrain components. Using the 5 lower attaching points for the rear cover, a rear anchor plate takes force from the rear part of the housing, transferring that force to the lower tubes of the torque arm. To receive force from the nose of the rearend housing, we use a 3/16" plate that closely fits around the housing in the area of the front pinion bearing. A bolt-on lower section allows us to fit the torque arm's nose plate over the 8.8's pinion flange, allowing for easy assembly. By attaching the torque arm directly to the 8.8's center housing, we eliminate the need to weld the axle tubes to the rear's center section, a necessity if one were using a conventional ladder bar style setup. The nose of the torque arm sits in the center of the car, directly under the driveshaft, and is connected to the front yoke..

...Front Yoke / Driveline Loop- This is the actual component that connects the torque arm's lifting force to the RX-7's chassis. The yoke's design allows the driveshaft to pass thru it's center, feeding the torque arm's lifting force into the RX-7's chassis at a point nearer the car's center-of-gravity, above the driveshaft, into the top of the transmission tunnel. As the yoke completely surrounds the driveshaft, it also functions as a built-in driveline loop. The yoke is essentially a floating loop around the driveshaft, hanging from the top of the transmission tunnel, with it's lower part connected to the nose of the torque arm.

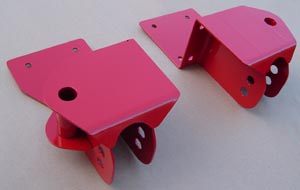

...Control Arms / Fr & Rr Bracket Set- As we based our lower control arms on those used on the '79-'85 1st gen RX-7, allowing use of low-cost parts sourced from a local wrecking yard for those on a budget. Our front control arm brackets locate using the your RX-7's existing rear chassis subframe mounting studs, but drilling is required to install the required back-up plates inside the car, further strengthening these attachment points, preparing them for extreme abuse. Our control arm's rear brackets attach directly to the 8.8's axle tubes (welding is required), and are spaced correctly to provide mounting points for your existing RX-7 rear springs and shocks.

...Control Arms / Fr & Rr Bracket Set- As we based our lower control arms on those used on the '79-'85 1st gen RX-7, allowing use of low-cost parts sourced from a local wrecking yard for those on a budget. Our front control arm brackets locate using the your RX-7's existing rear chassis subframe mounting studs, but drilling is required to install the required back-up plates inside the car, further strengthening these attachment points, preparing them for extreme abuse. Our control arm's rear brackets attach directly to the 8.8's axle tubes (welding is required), and are spaced correctly to provide mounting points for your existing RX-7 rear springs and shocks.

...Watts Linkage- Also sourced from the '79-'85 1st gen RX-7, the watts linkage provides the control that keeps the rear axle assembly centered under your car. Chassis brackets are provided to attach the outer ends of the watts linkage to your chassis.

Although it has not been confirmed yet, we believe our system is around the same weight as the original FC RX-7 rear/axles/subframe/trailing arms, possibly being even lighter. We will keep you posted as soon as we perform a detailed comparison.

To keep cost to a minimum, our TA/SA conversion is also available in kit form. The kit allows you to locally source your own rear housing/differential/axles/lower arms/watts linkage (welding required to attach our brackets to your axle tubes).

Pricing is as follows...

'86-'91 RX-7 TA/SA 8.8 Basic Kit includes...

'86-'91 RX-7 TA/SA 8.8 Basic Kit includes...

...Torque arm assembly (Mustang or Explorer 8.8)

...Torque arm rear anchor plate

...(5) grade 8 rear cover flange bolts

...Torque arm front yoke / driveline loop assembly

...(2) rubber chassis isolator bushing sets

...(4) Delrin T/A nose bushings

...(2) lower link front bracket assemblies

...(4) lower link front bracket back-up plates w/ (16) bolts/nuts

...(2) lower link rear bracket sets (weld-on)

...(2) lower shock adapter bushings

...watts linkage center pivot assembly (weld-on)

...watts linkage upper/left chassis bracket

...watts linkage lower/right chassis bracket

'86-'91 RX-7 TA/SA 8.8 Deluxe Package...

'86-'91 RX-7 TA/SA 8.8 Deluxe Package...

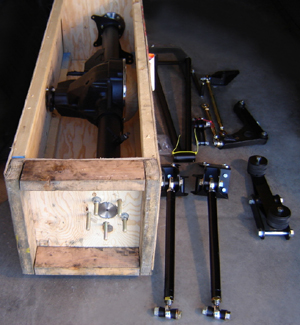

...Complete 8.8 rear, assembled w/ brackets attached

...Torque arm assembly

...Torque arm rear anchor plate

...Chrome rear housing cover

...(8) grade 8 rear cover flange bolts

...Torque arm front yoke / driveline loop assembly

...(2) rubber chassis isolator bushing sets

...(4) Delrin T/A nose bushings

...(2) lower link front bracket assemblies

...(4) lower link front bracket back-up plates w/ (16) bolts/nuts

...(2) lower link rear bracket sets (installed)

...(2) lower shock adapter bushings

...(2) RX-7 caliper brackets (installed)

...watts linkage center pivot assembly (installed)

...watts linkage upper/left chassis bracket

...watts linkage lower/right chassis bracket

...choice of gear ratio and housing width

...New billet 9" style housing ends- NO MORE C-CLIPS!!!

...New 31 spline TrackLok differential standard

...new forged 31 spline 5 lug 9" style axles w/ studs

...new bearings / seals

...new driveshaft / u-joints

NOTE-...lower links and watts rods/pivots pictured above are not included. Although we have fabricated upgrade replacements available, the TASA conversions are designed to use lower links and watts pivots/rods from a stock '79-'85 RX-7.

Available options include...

Available options include...

...Custom widths available at no extra charge

...Upgrade to a Detroit Locker, Tru-Trac, or Spool

...HD large dia adjustable lower links w/ choice of aluminum or Delrin bushings

...fabricated watts linkage w/ rod end style links and aluminum or Delrin pivot bushings

...RX-7 caliper mounting bracket set

...driveshaft exchange program available for prior customers

Our TA/SA Basic Kit also requires a few additional parts that can typically be obtained locally, potentially trimming quite a bit of money from your conversion. Those parts are...

...(2) '79-'85 RX-7 rear suspension lower links & pivot bolts

...(1) '79-'85 RX-7 rear watts linkage assembly

Here is the installed front yoke, which attaches to the top of the transmission tunnel with 2 bolts, using rubber to isolate vibrations and cushion shock loads. The driveshaft passes directly thru it's center. The front nose bushing of the torque arm sits above the lower edge of the RX-7's frame rails, and does not compromise ground clearance.

Here's a pic of the stock 2nd gen RX-7 4 lug brake rotors and calipers installed on a Mustang 8.8 rear. Note the simple bolt-on RX-7 caliper installation and factory appearance. The 5 lug RX-7 calipers/vented rotors are even easier to install, as the 5 lug RX-7 rotor already has the same 4-1/2" pattern as the 5 lug Mustang axles.

Here's a pic of the stock 2nd gen RX-7 4 lug brake rotors and calipers installed on a Mustang 8.8 rear. Note the simple bolt-on RX-7 caliper installation and factory appearance. The 5 lug RX-7 calipers/vented rotors are even easier to install, as the 5 lug RX-7 rotor already has the same 4-1/2" pattern as the 5 lug Mustang axles.

Here's a pic of our fabricated watts linkage for the 2nd gen RX-7, showing it's layout as it attaches under the RX-7. The large plate in the upper right of the pic attaches to the chassis using the large stud formerly used to attach the driver's side upper diff mount, as well as the 2 bolts that attach the left side of the sway bar to the chassis. The large "L" shaped bracket shown in the lower left side of the pic attaches to the bottom of the floor pan (in front of the passenger side axle tube) and uses a vertical strut that ties into an existing hole in the RX-7's sheetmetal "frame rail" in the area above the right rear caliper.

Here's a couple of pictures of a 1st gen RX-7 TASA conversion...while our system uses the same lower control arms, we completely eliminate the upper arms of the RX-7's stock 4 link, allowing us to narrow the rear significantly, making it possible to use easier to find wheels with less backspace.

For the 1st gen RX-7, we offer a smaller diameter coil spring option with threaded sleeves for adjustable ride height. Many spring rates are available.

The larger diameter of the 8.8 center section requires an adjustment to the length of the watts link's "links" to properly center the rear under the car. We supply sleeves that have the inside diameter perfectly sized, making it easy to simply salvage the original link ends for an economical solution that requires minor welding.

...Click Here for Ordering Information...

...Click Here for Ordering Information...

...If you have any questions for us, feel free to e-mail or call us at 360-391-1208 or 360-853-8219

...Our mailing address is:

Granny's Speed Shop

POB 814

Concrete, WA 98237

'86-'93 Ford Mustang 8.8...

...59-1/2" flange/flange width (exact same as the '86-'91 RX-7)

...4 on 4-1/4" lug pattern, easily re-drilled to RX-7 4 or 5 on 4-1/2" pattern

...came std w/tracloc clutch style diff

...Both L&R axles are 29-1/8" long 28 spline axles

...V8's came with 2.73 or 3.08 ratios

'87-'88 Thunderbird Turbo Coupe...

...61-1/2" flange/flange width

...same housing width as '86-'93 Mustangs, but 1" longer axles to make room for ABS sensors

...4 on 4-1/2" lug pattern (same as the RX-7), easily re-drilled to RX-7 5 on 4-1/2"

...came std w/tracloc clutch style diff

...Both L&R axles are 30-1/8" long 28 spline axles

...5spd cars came with 3.55 gears, automatic cars came with 3.73

...standard w/ disc brakes

'95-'01 Explorer...

...59-1/2" flange/flange width

...5 on 4-1/2" lug pattern

...un-equal length 31 spline axles (2-3/16" pinion offset)

...std disc brakes w/ 7/16" x 11.25 rotors